Recently, the company organized six employees from the workshop to Tangshan Panasonic Electric (China) Welding Technology College to participate in a ten-day "Robot Medium and Thick Plate Welding Technology" training. The training content is mainly based on the medium and thick plate software of Panasonic robots, focusing on the application of arc tracking and high-voltage sensing, helping students to start from scratch and learn the installation, debugging, operation and process application of medium and thick plate welding robot systems.

This training is conducted in the form of "theoretical teaching" + "topic question and answer". The theoretical teaching is mainly an introduction to the various functions and skills of the robot, and the topic question and answer is to explain each item based on the collected on-site topics.

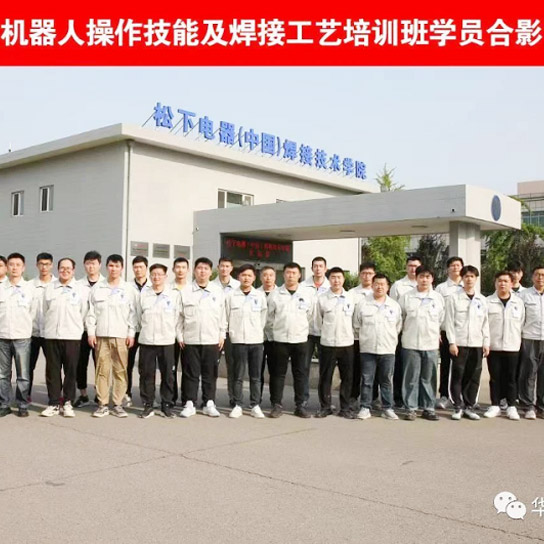

Employees' operation site

At the company's internal exchange meeting, the trainees shared their feelings about this training and put forward their own ideas and suggestions for the company's current oil pipe welding, box welding, pipe mouth welding, etc.

At the meeting, the company leaders also affirmed the learning results of the employees, and encouraged employees to apply what they learned, broaden their minds, and boldly try, and be good at discovering and solving problems at work and improving welding processes. It is said that the company will provide a better platform to cultivate more skilled talents and contribute to the improvement of the company's production process and quality.